Why elastomer is the top pick for most Rubber Keypads

Wiki Article

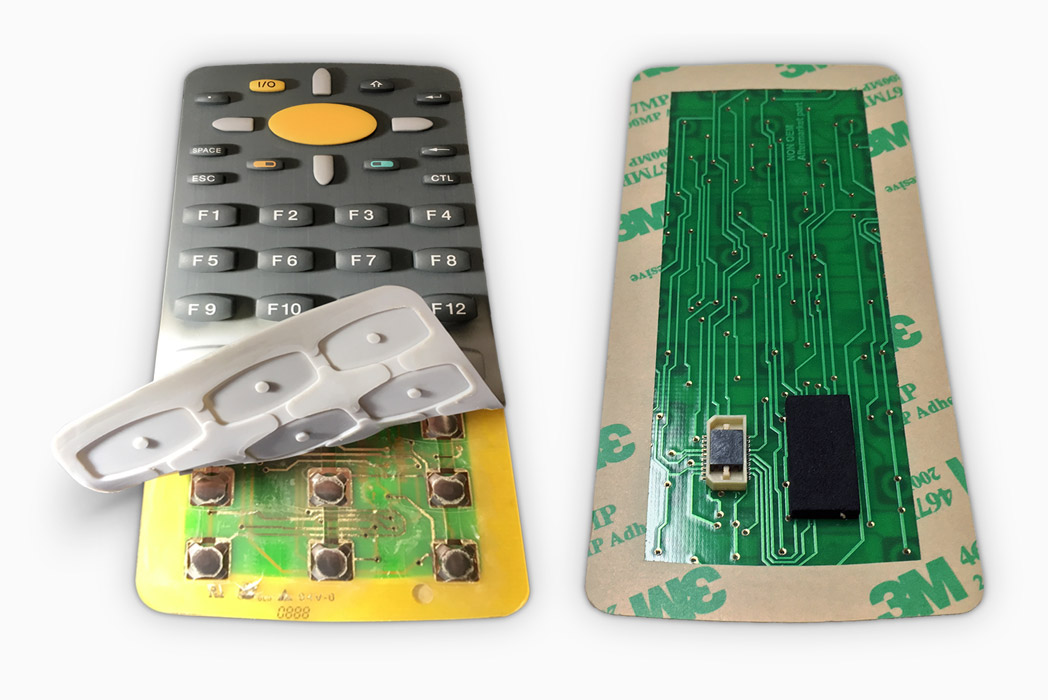

Discovering the Manufacturing Refine Behind Rubber Keypads and Their Value in Modern Tools

Rubber keypads are crucial in the performance of contemporary gadgets. Their manufacturing process involves cautious choice of materials and accurate techniques. Keypads are made to boost individual communication while making sure sturdiness and dependability. Comprehending exactly how these parts are made exposes their value throughout numerous applications. What variables contribute to their performance, and exactly how do these aspects affect customer experience? The responses may reshape perceptions of this everyday technology.Review of Rubber Keypads and Their Applications

Rubber keypads are versatile components extensively made use of in numerous electronic devices, ranging from customer electronics to industrial equipment. Their layout allows for a tactile action, making them a perfect choice for applications calling for individual communication. Generally located in products such as remotes, calculators, and medical devices, rubber keypads assist in convenience of use and ease of access.

In industrial setups, they offer important features in equipment and control board, where longevity and resistance to environmental elements are essential. The non-slip surface area boosts grasp, promoting dependability sought after problems. Furthermore, their light-weight nature and personalized forms enable producers to develop tailored solutions that fit certain requirements. With innovations in technology, rubber keypads continue to progress, including functions like backlighting and improved level of sensitivity. Generally, their adaptability and functional benefits add substantially to the effectiveness of numerous tools throughout multiple industries.

Materials Made Use Of in Rubber Keypad Manufacturing

Keypad manufacturing depends on an option of materials that enhance both performance and sturdiness. The main product utilized in the production of rubber keypads is silicone rubber, understood for its outstanding durability and flexibility. This product enables keypads to hold up against duplicated pressing without shedding shape or performance. Additionally, polycarbonate elastomers (TPE) are commonly utilized because of their ease of molding and capability to offer a soft-touch feel.Tinting representatives, such as pigments, are integrated to guarantee vibrant, long-lasting colors that boost aesthetic charm. Ingredients like anti-UV representatives and fire resistants might be mixed into the rubber to boost climate resistance and safety and security compliance. The choice of products directly affects the keypad's tactile response, long life, and total efficiency in numerous tools. Inevitably, the careful selection of these elements is vital for the manufacturing of high-grade rubber keypads that meet customer and sector needs.

The Style Refine of Rubber Keypads

When creating rubber keypads, the style process plays an essential duty in determining capability and user experience. Designers begin by defining the keypad's planned usage, thinking about elements such as the gadget it will certainly go along with and the target individual group. This first phase consists of laying out layouts that prioritize ergonomic aspects, making certain the keys are conveniently available and suitably spaced.Next, developers concentrate on the responsive comments desired from the keypads, which influences the selection of materials and key shapes. Prototyping is vital in this stage, permitting developers to evaluate numerous designs for comfort and responsiveness.

Production Techniques for Rubber Keypads

The production process for rubber keypads involves a series of accurate techniques that guarantee top quality and performance. Originally, fluid silicone rubber (LSR) is typically utilized due to its toughness and adaptability. The procedure begins with blending the raw materials, including silicone, colorants, and healing agents. This blend is after that injected into mold and mildews developed to shape the keypads accurately.

Following shot, the shaped keypads undertake curing, a home heating process that strengthens the product (Rubber Keypads). This is usually executed in a press, guaranteeing the keypads attain the wanted solidity and resilience

High Quality Control Measures in Production

To ensure that rubber keypads meet high standards of top quality and functionality, strenuous quality assurance measures are executed throughout the production process. These actions begin with resources evaluation, ensuring that just the highest-grade elastomers are made use of. During the production stage, operators perform routine checks to check criteria such as temperature level, stress, and blending times, important for attaining consistent item quality.Post-production, each batch of keypads goes through extensive testing, including responsive feedback assessments and resilience tests to assess efficiency under different problems. Aesthetic examinations are likewise performed to determine any type of flaws, such as bubbles or incongruities in texture. In addition, conformity with market standards is confirmed, making sure that the keypads fulfill safety and functionality standards.

The Role of Innovation in Keypad Growth

Technology plays a crucial function in the advancement of rubber keypads by allowing innovative manufacturing techniques that enhance precision and performance. In addition, innovative material option permits improved toughness and responsiveness in keypad performance. These advancements not only simplify production yet likewise raise the overall top quality of the last product.Advanced Manufacturing Techniques

Developments in manufacturing methods revolutionize the production of rubber keypads, enhancing both performance and precision. Technologies such as injection molding and 3D printing have changed traditional processes, making it possible for manufacturers to create complicated styles with minimized waste and boosted turn-around times. Automation plays an essential role in this development, improving setting up lines and decreasing human mistake. In addition, computer-aided design (CAD) software application permits complex find here customization, making sure that keypads fulfill details individual requirements. Quality control procedures have actually likewise progressed, incorporating real-time monitoring systems that spot flaws early in the manufacturing cycle. These developments not just improve the resilience and functionality of rubber keypads yet likewise support the expanding demand for personalized solutions in numerous markets, from consumer electronic devices to automotive applications.Ingenious Product Selection

The advancement of producing techniques has actually paved the method for innovative product choice in rubber keypad advancement. Advances in polymer scientific research have actually presented materials that enhance longevity, versatility, and tactile responses. Makers now make use of polycarbonate elastomers (TPE) and silicone compounds, which provide premium resistance to use and ecological factors. These products enable for the creation of keypads that can withstand extended use while preserving aesthetic charm. Additionally, the combination of additives and layers improves performance, such as improving grasp and decreasing friction. The option of products is essential, as it straight impacts the efficiency and long life of keypads in different devices, from consumer electronics to commercial devices. This innovative strategy proceeds to shape the future of keypad design and use.The Effect of Rubber Keypads on User Experience

Rubber keypads greatly affect user experience through their improved responsive feedback, which permits more accurate communication. Furthermore, their toughness and long life add to consistent efficiency over time, decreasing the requirement for constant replacements. This combination of features makes rubber keypads a preferred selection in different applications, eventually impacting customer satisfaction.Boosted Tactile Feedback

Enhancing responsive action significantly affects customer experience, particularly in gadgets that count on keypads for interaction. Rubber keypads provide an one-of-a-kind combination of gentleness and strength, allowing individuals to feel distinctive feedback with each press. This responses reinforces a feeling of control and precision, vital in applications ranging from smartphones to commercial tools. Individuals commonly report greater satisfaction and performance when engaging with gadgets that feature properly designed rubber keypads, as they facilitate quicker and more accurate input. In addition, the ergonomic style of these keypads can lower finger exhaustion, advertising longer use durations without pain. Overall, the boosted tactile feedback offered by rubber keypads substantially contributes to an extra pleasurable and user-friendly individual experience in modern-day innovation.Sturdiness and Long life

A crucial aspect of customer experience with rubber keypads hinges on their sturdiness and durability. These keypads are created to endure considerable usage, withstanding deterioration that often affects various other materials. The durable nature of rubber assurances that keypads preserve their performance and appearance gradually, which is vital for tools often made use of in various settings. Users take advantage of the reliability of rubber keypads, as they can sustain direct exposure to dampness, dirt, and temperature variations without weakening. This strength not just boosts individual complete satisfaction yet likewise reduces the demand for regular replacements, eventually adding to cost-effectiveness for manufacturers. Essentially, the durability of rubber keypads significantly influences the general efficiency and individual experience in modern-day gadgets.Frequently Asked Inquiries

For How Long Do Rubber Keypads Typically Last in Devices?

Rubber keypads usually last between 5 to one decade, relying on use, environmental elements, and top quality of materials used (Rubber Keypads). Normal deterioration can shorten their lifespan, influencing functionality and user experience graduallyCan Rubber Keypads Be Customized for Certain Applications?

Rubber keypads can without a find out this here doubt be personalized for specific applications, enabling modifications in dimension, structure, shape, and color. This flexibility allows makers to produce tailored solutions that fulfill diverse customer needs and enhance capability in numerous tools.Are Rubber Keypads Ecologically Friendly?

Rubber keypads are frequently ruled out eco-friendly due to their petroleum-based materials. Improvements in sustainable manufacturing techniques and the growth of bio-based alternatives are slowly boosting their environmental effect in different applications.What Are Typical Issues Dealt With During Rubber Keypad Production?

Usual concerns encountered during rubber keypad manufacturing consist of irregular worldly quality, mold issues, inappropriate healing times, bond failures, and difficulties in achieving accurate responsive comments. These issues can lead to reduced item efficiency and customer dissatisfaction.How Do Rubber Keypads Compare to Various Other Types of Trick Switches?

Rubber keypads supply a softer feeling and quieter operation compared to mechanical switches, which provide responsive responses. Nonetheless, rubber keypads might break faster and do not have the Source precision that some individuals favor in high-performance applications.The key product made use of in the manufacturing of rubber keypads is silicone rubber, recognized for its outstanding resilience and flexibility. When producing rubber keypads, the style procedure plays a vital role in identifying capability and customer experience. Rubber keypads significantly affect individual experience with their improved tactile feedback, which enables for even more accurate communication. Customers usually report greater satisfaction and effectiveness when communicating with devices that feature properly designed rubber keypads, as they facilitate quicker and more exact input. A crucial facet of customer experience with rubber keypads exists in their toughness and long life.

Report this wiki page